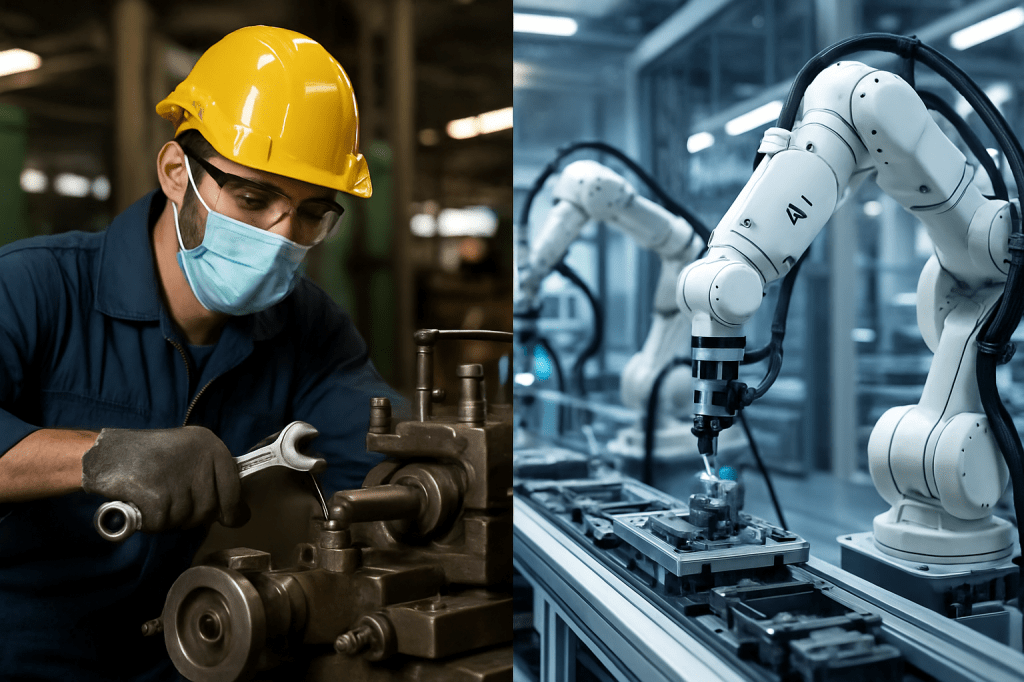

Technicians vs AI-Powered Manufacturers: Comparison

Role of Technicians in Manufacturing Technical Support & Troubleshooting: Technicians provide hands-on support for equipment and processes, addressing machine breakdowns, troubleshooting issues, and implementing corrective maintenance activities.

Quality Assurance: They check product quality, run tests, and ensure products meet internal and regulatory standards, intervening when deviations occur.

Operation & Maintenance: Technicians set up, operate, monitor, clean, and maintain machinery to ensure smooth and efficient production.

Documentation & Reporting: They maintain clear records of maintenance, productivity, and incidents, ensuring compliance with procedures.Process Optimization: Technicians apply lean manufacturing and Six Sigma principles to minimize waste and improve process efficiency.

Collaboration: Technicians work with multiple departments, including production, quality, engineering, and safety teams.

AI-Powered Manufacturing: Capabilities and Benefits

Automation & Optimization: AI automates repetitive tasks, self-optimizes production lines, and predicts equipment failures for proactive maintenance, reducing downtime and human errors.

Data-Driven Decisions: AI systems analyze large data sets to detect patterns, forecast demand, manage inventory, and recommend strategic improvements.

Quality Control: AI vision systems inspect products faster and more accurately than humans, ensuring higher product quality.

Innovation: AI enables generative design, rapid prototyping, and digital twin simulations, supporting faster and more advanced innovation.

Safety & Sustainability: AI-controlled cobots handle hazardous tasks, improving workplace safety. AI also optimizes resource use and reduces energy consumption, promoting sustainability.

Upskilling & Job Satisfaction: AI frees workers from routine tasks and supports skill development, enabling technicians to focus on higher-level responsibilities and leading to greater job satisfaction.

Supply Chain Optimization: AI enhances inventory management, demand forecasting, and resource allocation for efficient supply chain operations.

Key Differences

| Aspect | Technicians | AI-Powered Manufacturer |

|---|---|---|

| Core Function | Manual troubleshooting, operation | Automation, optimization via AI |

| Decision Making | Human expertise, experience | Data-driven, predictive algorithms |

| Quality Control | Inspection, hands-on QA | AI vision systems, real-time feedback |

| Maintenance | Preventive/corrective by technicians | Predictive (AI), less downtime |

| Innovation | Incremental process improvements | Rapid prototyping, generative design |

| Safety | Procedural adherence | AI/cobot-assisted hazardous tasks |

| Job Role Evolution | Hands-on, technical | Focused on supervision, upskilling |

| Scalability | Limited by human capacity | Broad, rapid, data-driven scalability |

| Sustainability | Manual resource management | AI-optimized resource managem |

Collaboration and Integration

Most modern factories are moving toward human-AI collaboration rather than replacing technicians entirely. AI handles routine, optimization, and monitoring tasks, while technicians focus on areas requiring manual dexterity, creativity, and judgment.Technicians remain essential for complex problem-solving, implementing AI-driven suggestions, and adapting to new technologies.

Challenges and Limitations

AI in manufacturing needs high-quality data, ongoing monitoring, and expert oversight. Not all tasks can be fully automated—especially those requiring subjective decision-making or creative problem-solving.

Technology integration may require continuous learning and adaptation for technicians to fully leverage AI systems.

In summary, technicians provide irreplaceable hands-on technical expertise, troubleshooting, and human oversight, while AI-powered manufacturing brings speed, scalability, automation, predictive insights, and advanced innovation. The future is collaborative, with both human technicians and AI systems working together to drive quality, efficiency, and safety in manufacturing.

Leave a comment